CNC milling and Turning

We specialize in the production of components especially for the hydraulics and pneumatics industries. All parts are manufactured on state-of-the-art CNC machines operated by experienced employees. Production preparation is carried out in following technologies SolidWorks and Draftsight and the programs themselves are then prepared in the software environment SolidCAM. This enables us to significantly shorten the preparation of particularly complex products during low series production and offers an competetive price.

We can machine almost any metal or plastic. Options include milling on up to 4 axes simultaneously on our vertical milling machines.

However where we trully excel is:

Machining of complex parts on our turn-mill centers equipped with live tooling.

Large-series production of hydraulic and pneumatic components (Hydraulic stems, Hydraulic ferrules, Collars) on our swiss type lathes.

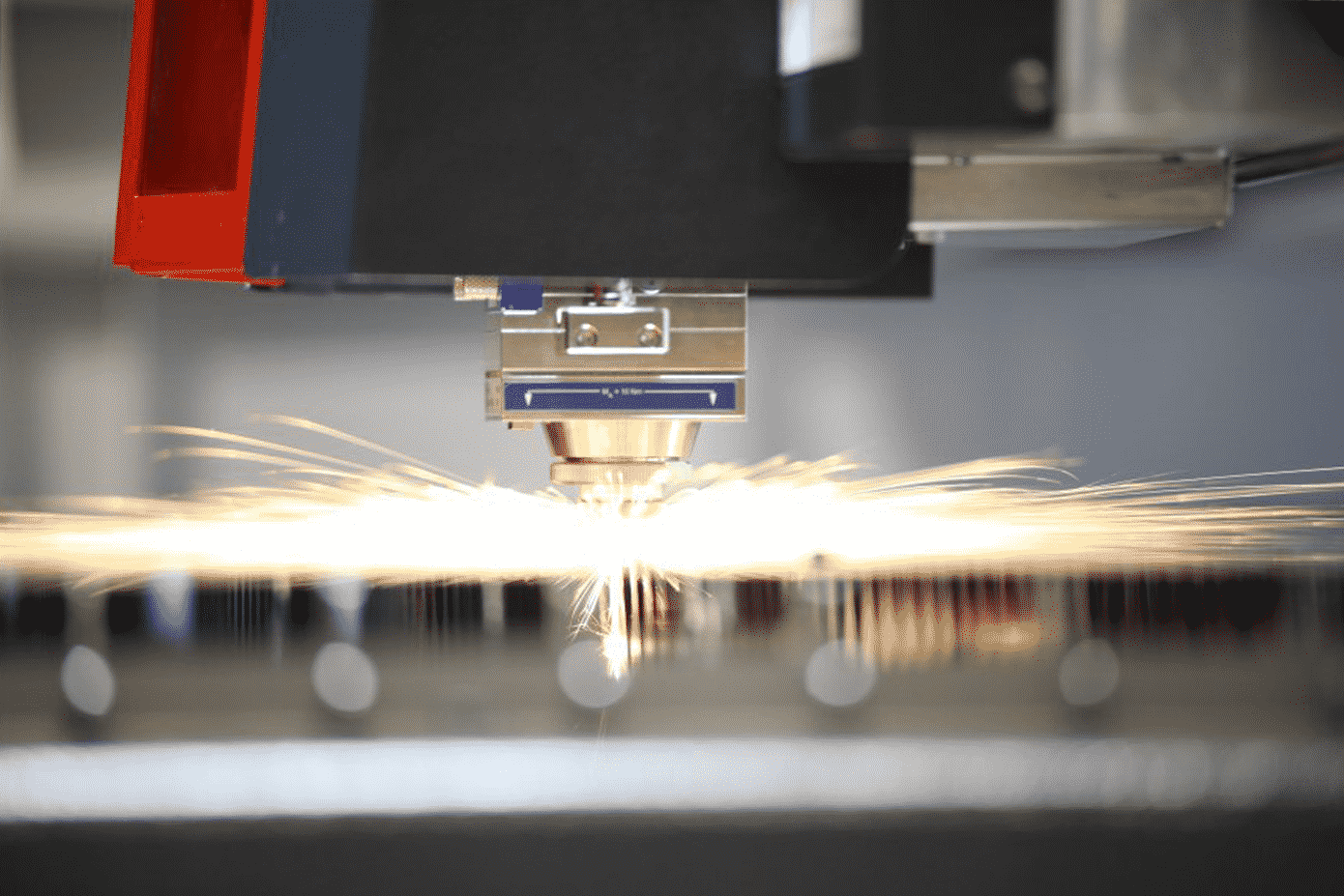

Fiber laser cutting and sheet metal bending

CNC fiber laser cutting offers precision and speed when cutting different types of materials. This technology uses a high-powered laser beam to cut metals, plastics and other materials with incredible precision. The process is cost-effective, making it a popular choice for industries requiring intricate and detailed cuts.

After part is laser-cut with a power of up to 6kW and sheets up to 3000x1500mm in size, we can offer precise bending on our 200t bending CNC press brake.

In the field of sheet metal processing we also offer laser hand welding of metal sheet parts with power up to 1500W