In the fast-paced world of CNC machining, the ability to efficiently produce complex, precise parts is essential. At TG Machinery, we’re always seeking ways to optimize our processes and expand our capabilities. Recently, we took on a project of designing and building our own 4th axis cradle for our OKUMA milling machine. This custom solution will not only improve our workflow but will also open up new possibilities for machining more intricate parts. Here’s a closer look at how we accomplished it.

Why We Needed a 4th Axis Cradle

Adding a 4th axis to a CNC milling machine greatly expands its versatility. A 4th axis cradle allows the machine to rotate workpieces around a horizontal axis, enabling more complex geometry and making operations like contouring, drilling on multiple surfaces, and machining intricate profiles much more efficient. When we realized that our OKUMA milling machine could be even more valuable with this addition, we evaluated the options on the market. However, we found that a custom solution would be the best fit for our unique production requirements.

Step 1: Planning and Design

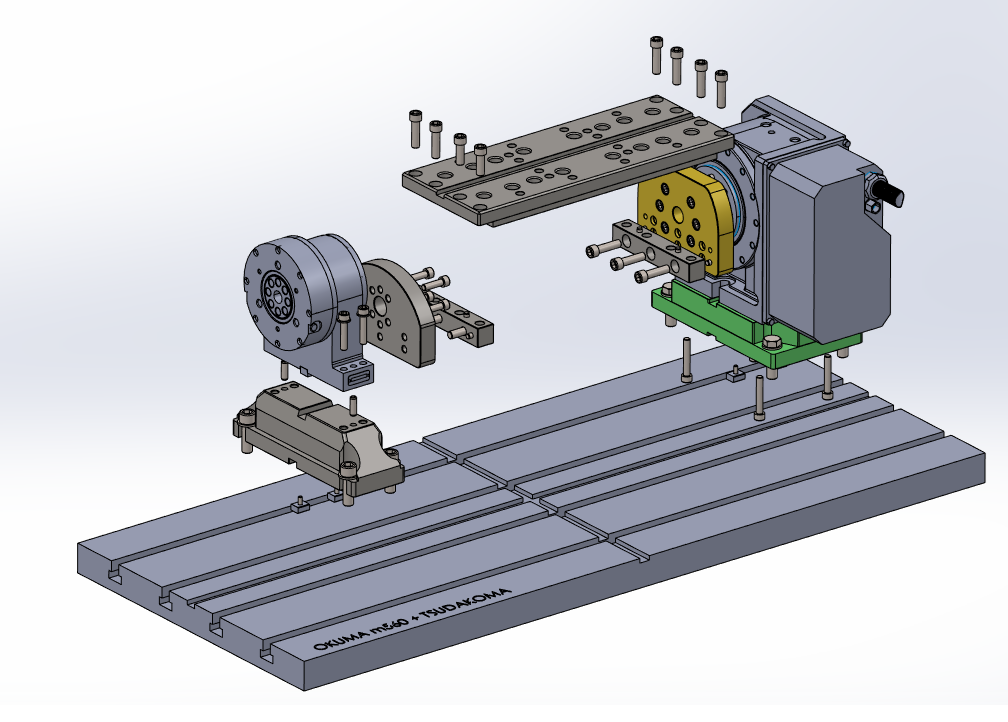

The first step in this journey was to design a cradle that would seamlessly integrate with our existing OKUMA milling machine while providing robust support for the types of materials and components we regularly work with. Our engineering team set clear goals for the project:

1. **Compatibility**: The cradle had to work perfectly with TSUDAKOMA main and auxiliary bearing

2. **Stability and Precision**: To achieve our desired precision, the cradle needed to be stable enough to avoid any vibration or deflection during heavy milling.

3. **Ease of Use**: We wanted the cradle to be easy to mount and dismount, reducing setup time and allowing our operators to switch between different operations with minimal downtime.

Using CAD software, we designed a structure that met all these requirements.

Step 2: Precision Machining and Assembly

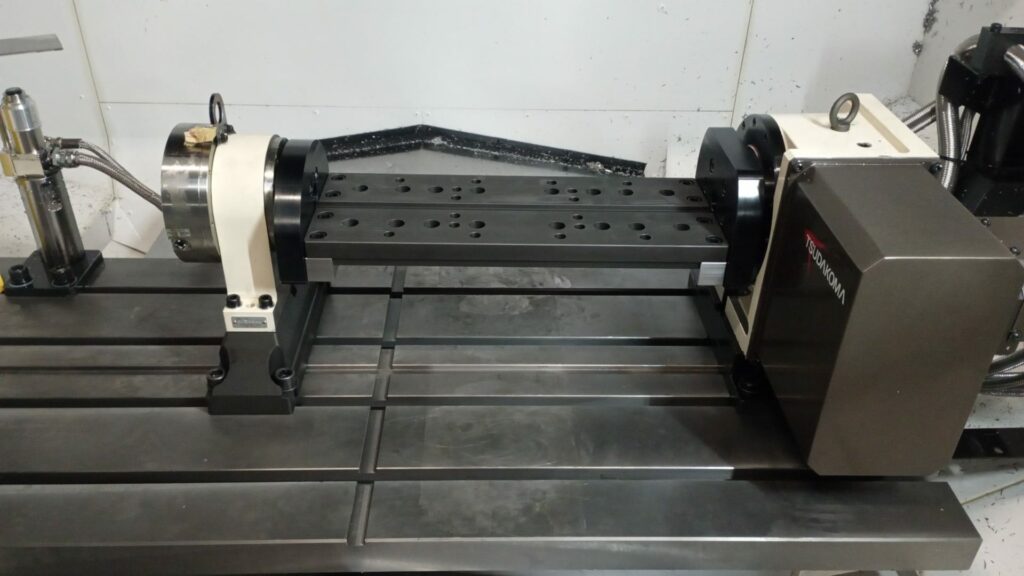

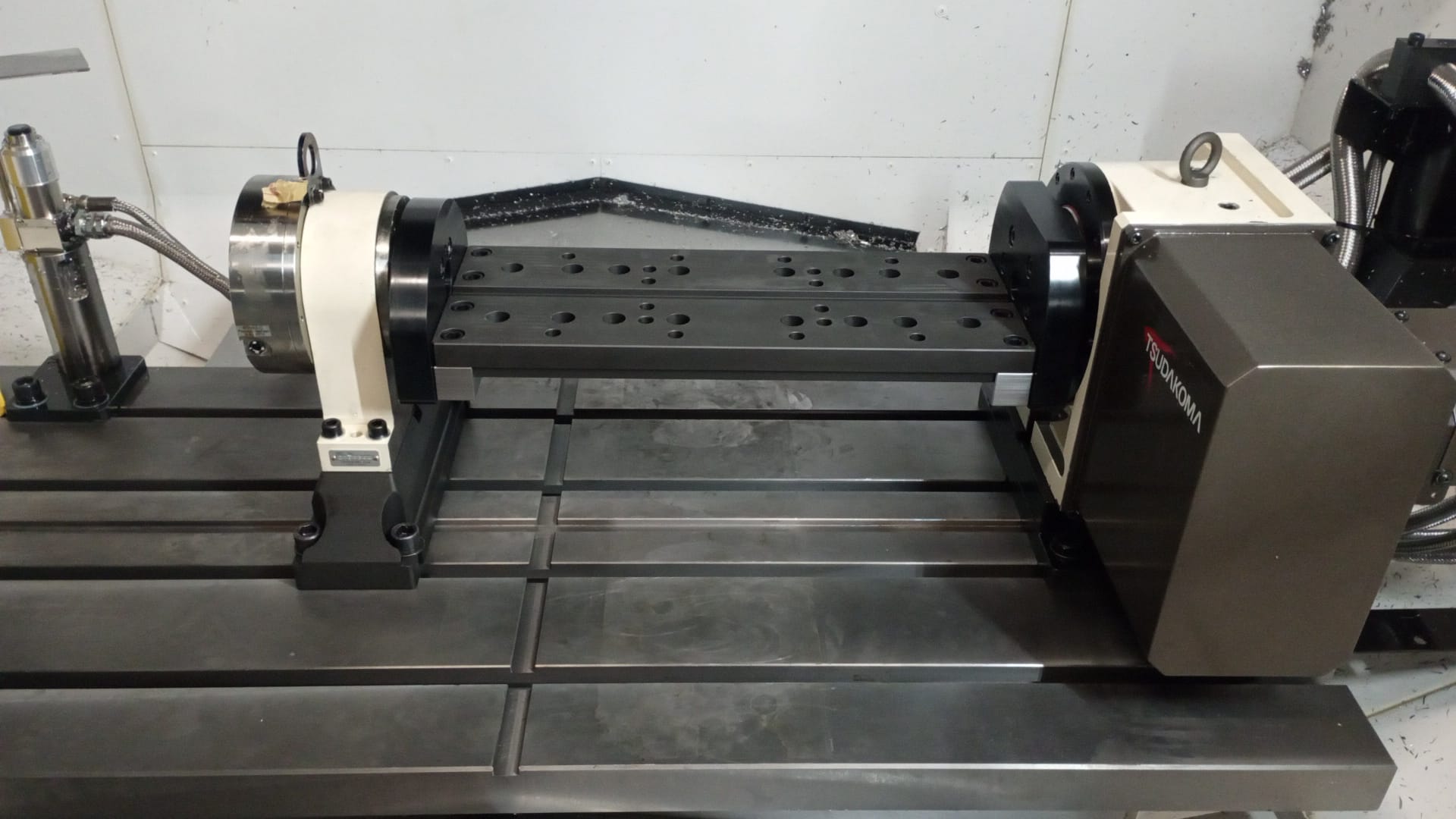

Once we had a final design and selected materials, it was time to bring the cradle to life. Using our own CNC machines, we precisely cut and shaped the components of the cradle. Every component was machined to exact tolerances to ensure the cradle would fit perfectly and integrate with our TSUDAKOMA bearings.

Our team then carefully assembled the cradle, double-checking each bolt and joint to guarantee stability. This meticulous attention to detail was essential, as even the slightest misalignment could affect performance and lead to inaccuracies in the final product.

Step 3: Testing and Calibration

After assembly, we mounted the cradle on the OKUMA and conducted a series of tests to verify that everything was functioning as expected. After assembly the 4th axis cradle is still to undergo precise measurement of Z level of both main and auxilliary bearing. After measurement – the platform under auxilliary bearing will be precisely ground to achieve perfec cocentricity of both bearings when assembled. Doing this will get us perfect kinematic conditions and limit stresses on both bearings.

The Future of Custom Machining at TG Machinery

The success of our custom-built 4th axis cradle has inspired us to continue exploring ways to enhance our machining capabilities. As we move forward, we’ll keep innovating and investing in custom solutions that enable us to offer our clients the most efficient and precise machining services available.

Whether you need high-precision parts with complex geometries or you’re looking for a reliable partner for your production needs, TG Machinery is here to deliver. Our commitment to quality, innovation, and customer satisfaction is reflected in everything we do – including the development of our own machining solutions.

Conclusion

By designing and building our own 4th axis cradle, we’ve taken an important step toward expanding our capabilities and improving our services. This custom addition to our OKUMA milling machine is a testament to our engineering expertise and dedication to providing high-quality, innovative solutions for our clients. If you’re interested in learning more about our capabilities or how we can help you with your next project, don’t hesitate to contact us!

At TG Machinery, we don’t just operate CNC machines – we create solutions.

Napsat komentář